Enhancing Workplace Safety with Advanced Safety Relays

Enhance workplace safety with advanced Safety Relays:

In today’s fast-paced industrial environment, the importance of workplace safety cannot be overstated. Ensuring the safety of employees and machines is a fundamental responsibility of employers, which can significantly reduce the risk of accidents, increase productivity and minimize associated costs. A key component of modern safety systems, safety relays are devices used to monitor and ensure the proper functioning of safety-related components in industrial machinery and processes. By inteGrating advanced safety relays into your safety strategy, you can significantly improve workplace safety and create a safe working environment.

Safety relays are specialized devices designed to ensure machinery and processes function properly under normal conditions and respond appropriately when faults are detected, minimizing risk. Safety relays are an integral part of various safety-related functions such as emergency stops, light curtains, door interlocks and guarding systems. They monitor multiple inputs and control outputs to execute safety shutdowns or other necessary safety responses to protect personnel and equipment.

1. Monitoring and Control: Safety relays continuously monitor the operating status of safety devices and the controlled machinery or process. They ensure safety protocols are being followed by checking position, speed, temperature and other critical parameters. When an abnormal or unsafe condition is detected, the safety relay triggers corrective action, such as machinery stopping or alarm activation.

2. Redundancy and Fault Tolerance: Advanced safety relays are designed with redundancy and fault tolerance, which means they have multiple channels and fail-safe mechanisms to deal with single point failures. This makes them highly reliable and ensures that safety functions continue to operate properly even if one component fails.

3. Isolation: Safety relays provide electrical isolation between control circuits and safety functions, which is critical to protecting sensitive components and preventing unintended actions that could result in hazardous situations.

Enhance workplace safety with advanced safety relays

Integrating advanced safety relays into your industrial systems can significantly improve workplace safety. The specific method is as follows:

1. Improved risk management: By deploying safety relays, you can improve the protection of your employees and machines by eliminating potential risks before they lead to accidents. Advanced safety relays provide precise control and monitoring, ensuring safety systems are activated before an incident escalates.

2. Compliance with standards and regulations: Safety relays help ensure compliance with international safety standards such as EN ISO 13849, IEC 61508, and OSHA regulations. Not only does compliance protect employees, it also helps avoid legal challenges and potential fines.

3. Automation and Efficiency: Adding advanced safety relays helps automated processes run more smoothly. They enable a quick and controlled response to abnormal situations, minimizing downtime and increasing overall productivity. With a safety relay installed, the machine can safely resume operation after an interruption.

4. Customizable safety solutions: Modern safety relays are highly configurable, allowing the safety functions to be flexibly tailored to specific machinery or processes. This customization ensures that safety measures are precisely matched to operational requirements, reducing the likelihood of false triggering or unnecessary downtime.

Types and Applications of Safety Relays

Safety relays are available in a variety of configurations to suit different applications. Understanding the most common types and their uses is essential to optimizing workplace safety.

1. Single-function safety relays: These relays perform a specific safety function, such as emergency stop monitoring or guard interlocking. They are ideal for simple systems where a single security measure is sufficient.

2. Multifunctional safety relays: These relays integrate multiple safety functions into a single device, providing comprehensive protection for complex machinery and processes. They are very efficient for applications that require coordination of multiple safety functions.

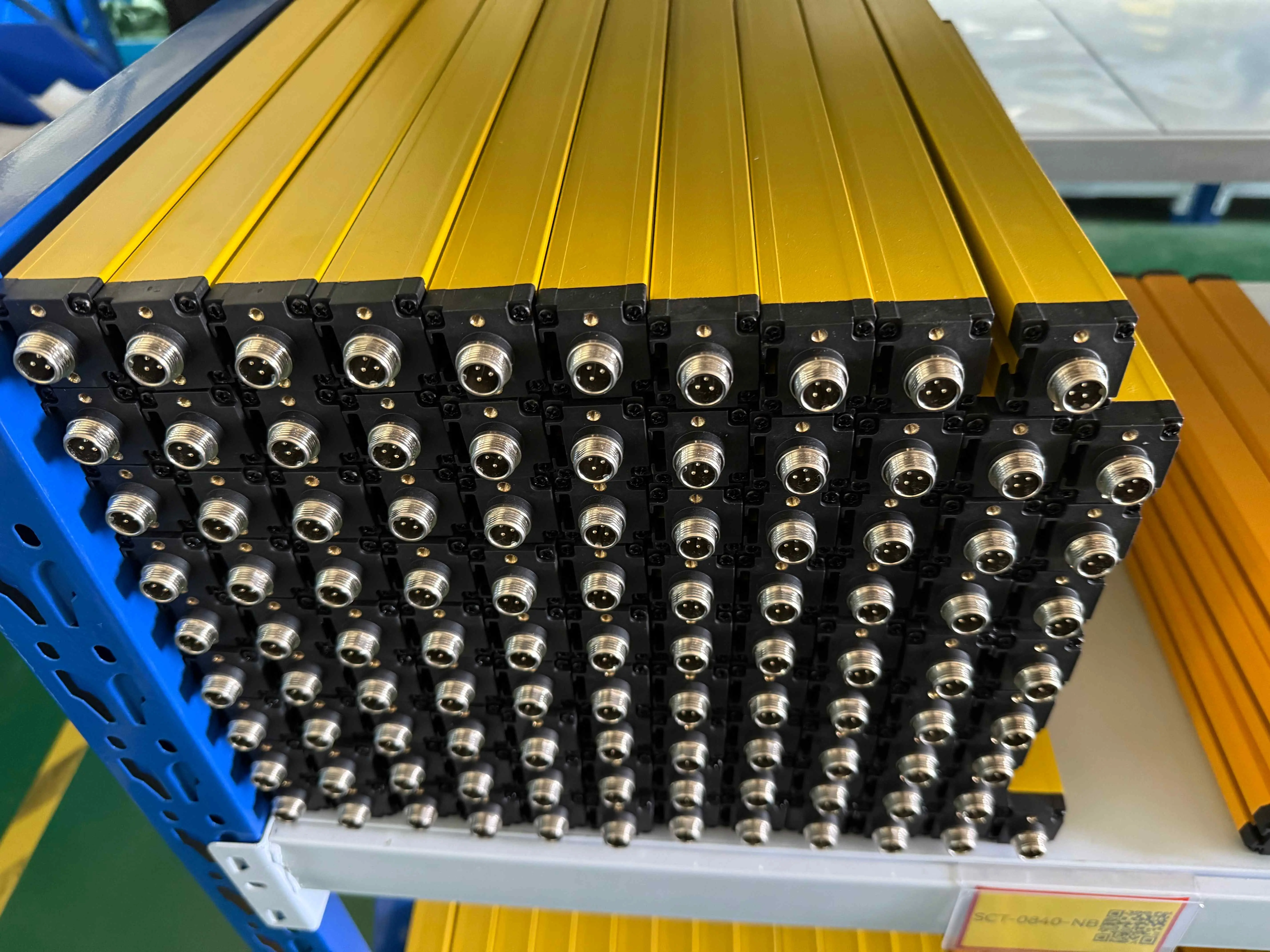

3. Modular safety relays: These relays are scalable and flexible, allowing more modules to be connected as safety requirements change. They facilitate expansion of facilities or systems with evolving security requirements.

4. Programmable Safety Relays: For advanced applications, programmable safety relays offer a wide range of functions and user-defined logic to create customized safety solutions. They are suitable for complex systems with extremely high requirements on safety and automation.

in conclusion

In summary, safety relays are essential to maintaining workplace safety in modern industrial environments. By adopting advanced safety relays, companies can effectively manage risks, ensure compliance with strict safety standards, and promote a safety culture that protects people and equipment. Integrating these devices into your security strategy can improve operational efficiency and foster a safe and productive work environment. As industrial technology continues to advance, investing in advanced safety relays will continue to be a critical step in ensuring future workplace safety.