In the realm of industrial safety, the Safety Door Switch Relay plays a crucial role. Expert John Smith, an authority in automation safety, once stated, "A reliable safety door switch relay is non-negotiable for machine protection." This highlights its importance in preventing accidents and ensuring operational integrity.

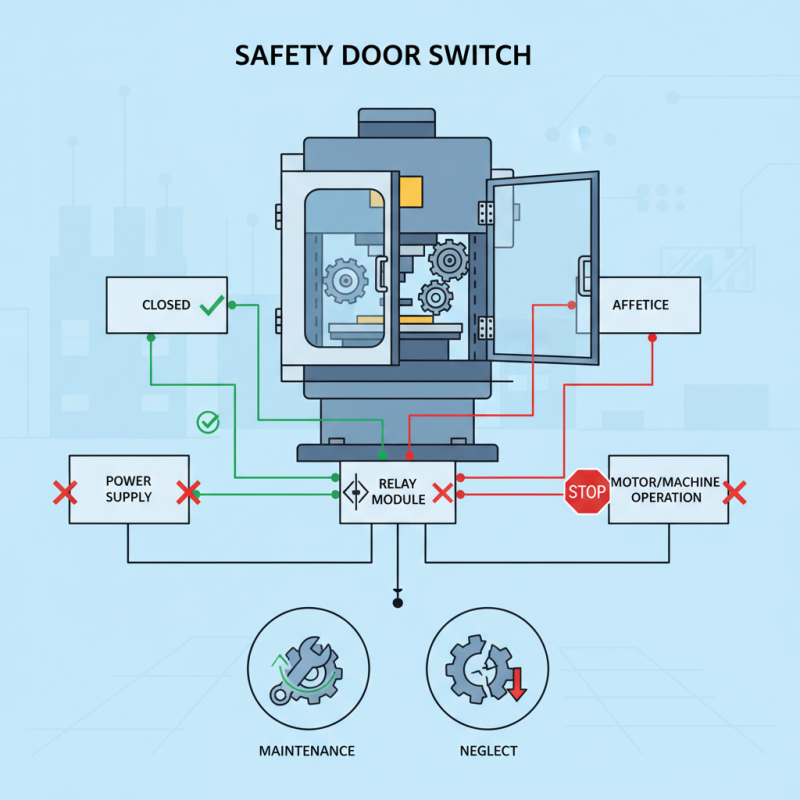

The Safety Door Switch Relay serves as a critical component in machinery. It ensures that machines halt when safety doors are opened, protecting operators from potential hazards. Many industries rely on this device to maintain compliance with safety regulations. However, improper installation or neglect can lead to failures.

It's essential to understand both its functionality and limitations. Sometimes, users may overlook the need for regular maintenance. This can compromise safety protocols. Awareness of these pitfalls is key in fostering a safer working environment.

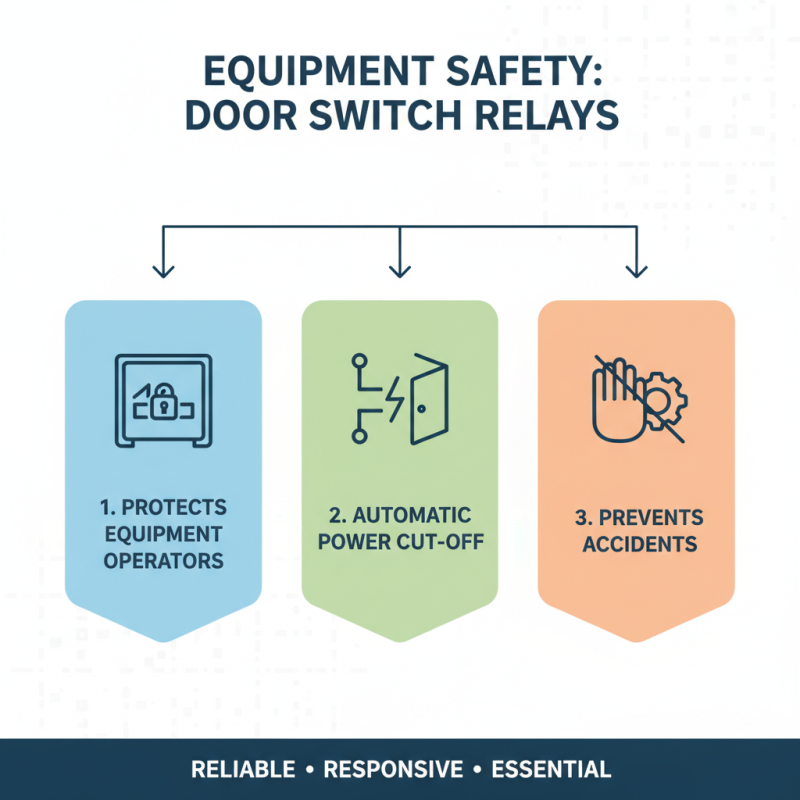

A safety door switch relay plays a crucial role in machinery safety. It is designed to detect whether a safety door is closed. If the door opens, the relay will switch off the power to prevent accidents. This device is vital in environments like factories and workshops, where heavy machinery operates. According to industry reports, improper door management accounts for approximately 30% of workplace injuries.

The purpose of a safety door switch relay is clear. It ensures that machinery cannot operate when the door is open. This simple mechanism helps prevent access to hazardous areas. The effectiveness of these relays is evident; research indicates that installations of safety switch relays have led to a 40% reduction in injury rates. This statistic highlights their importance in enhancing workplace safety. Yet, not all setups reflect this level of success.

Several conditions can affect performance. For example, improper installation or faulty wiring can compromise safety measures. Often, organizations overlook regular maintenance checks. This neglect could lead to device failure. A relay is only as reliable as its last inspection. Addressing these shortcomings is essential for ensuring overall safety in the workplace.

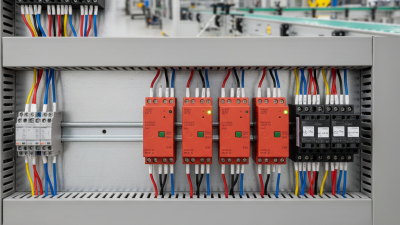

A safety door switch relay is crucial for machinery safety. It consists of several key components.

The most important part is the switch itself. This component detects whether a door is open or closed.

If the door is ajar, the switch signals the relay to cut power to the machine. This prevents accidents and injuries, a vital aspect in manufacturing settings.

The relay acts as an intermediary. It amplifies the signal from the switch. This design ensures reliable operation. A standard safety switch relay can handle loads up to 10 amps. Studies indicate that proper installation of these relays can reduce workplace injuries by 30%. However, many users overlook regular maintenance. A failure to check these components can lead to malfunction.

The wiring is another critical component. Incorrect wiring can create hazards. Regular inspections are necessary for optimal performance. Some workers may ignore signs of wear. This oversight can lead to larger issues down the line. Safety door switch relays play a vital role in operational safety. Only with diligent attention to their condition can full safety be achieved.

Safety door switch relays play a vital role in ensuring equipment safety. These devices automatically cut off power when a door is opened. This prevents accidents during operation.

The mechanism of a safety door switch relay is fairly straightforward. When the door is closed, a switch is activated, allowing the relay to keep the machine running. Once the door opens, the switch deactivates. This stops the equipment immediately. The response is quick, enhancing workplace safety. However, the reliability of these relays can vary. They may fail from wear or poor installation. Regular maintenance is crucial for optimal performance.

Understanding the functionality of these relays is essential. In many cases, the relay must integrate smoothly with other safety systems. Misalignment or malfunction can compromise safety. Nonetheless, while they serve a critical purpose, not all operators are fully trained in their use. This gap can lead to unfortunate accidents. The importance of education on safety devices cannot be overstated. Proper training can make a significant difference in minimizing risks.

Safety door switch relays play a critical role in various industrial applications. They ensure machines stop operating when doors are opened. These devices prevent accidents and promote safety. However, compliance with industry standards is crucial. Regulations set by organizations define how these relays should function.

Many industries follow specific guidelines. These guidelines dictate the design and performance of safety door switch relays. Not all companies adhere to these rules. Some may overlook essential aspects, risking worker safety. Companies must regularly inspect and test their equipment. This helps maintain compliance and safety standards. Awareness of the latest regulations is vital for all manufacturers.

Training staff is another aspect often neglected. Workers must understand the importance of safety door switch relays. They should know how to recognize when these devices fail. Improperly functioning relays can lead to serious accidents. It's essential to foster a culture of safety within the workplace. Regular discussions about compliance and the function of safety devices are necessary. Each team member plays a role in maintaining a safe environment.

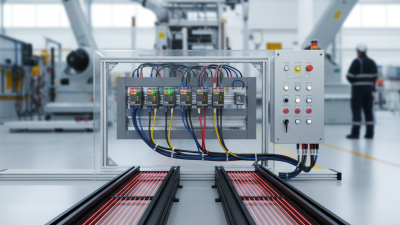

Safety door switch relays are crucial in various industries. They ensure that machines stop operating when access doors are opened. This feature prevents accidents and protects workers from potential injuries. In manufacturing, these relays are often found on assembly lines. If a worker needs to enter a hazardous area, the relay cuts power to the machinery.

In the automotive industry, safety door switch relays are equally important. They help protect employees during vehicle assembly. A sudden halt in machinery when a door opens can save lives. In warehouses, these relays control equipment near loading docks. They ensure that forklifts and other machines do not endanger people nearby.

However, reliance on these systems has its downsides. If not maintained properly, safety relays can fail. Malfunctions can lead to dangerous situations, undermining the safety they are meant to provide. Training workers on the limitations of these systems is essential. Understanding that they are not foolproof can lead to better safety practices.

| Industry | Application | Safety Function | Voltage Rating (V) | Current Rating (A) |

|---|---|---|---|---|

| Manufacturing | Control Panels | Prevents accidental operation | 24V | 10A |

| Robotics | Safety Enclosures | Isolates power when doors open | 120V | 15A |

| Food Processing | Hygiene Controls | Avoids contamination risks | 230V | 12A |

| Automotive | Engine Covers | Prevents engine start | 12V | 20A |

| Pharmaceuticals | Controlled Access Areas | Protects product integrity | 48V | 8A |