In today's fast-paced industrial environment, ensuring workplace safety has become a paramount concern for organizations worldwide. One critical component in the realm of hazard prevention is the use of Two Hand Safety Relays, which serve as a vital mechanism to mitigate risks associated with machinery operation. According to a report by the International Labor Organization (ILO), approximately 2.78 million work-related fatalities occur every year, highlighting the urgent need for effective safety measures. Two Hand Safety Relays are specifically designed to require simultaneous activation by an operator, significantly reducing the likelihood of accidental machine start-up and enhancing operator safety.

The implementation of Two Hand Safety Relays not only safeguards operators but also adheres to safety standards that govern industrial operations. The European Machinery Directive stipulates safety requirements for machinery, with a focus on reducing risks associated with hazardous tasks. Studies indicate that the proper use of safety relays can lead to a significant decrease in workplace injuries, potentially lowering incident rates by over 50%. By integrating these relays into operational protocols, organizations can create safer working environments while fostering a culture of safety that prioritizes employee well-being. As industries evolve and automation becomes more prevalent, the role of Two Hand Safety Relays in hazard prevention will continue to be indispensable.

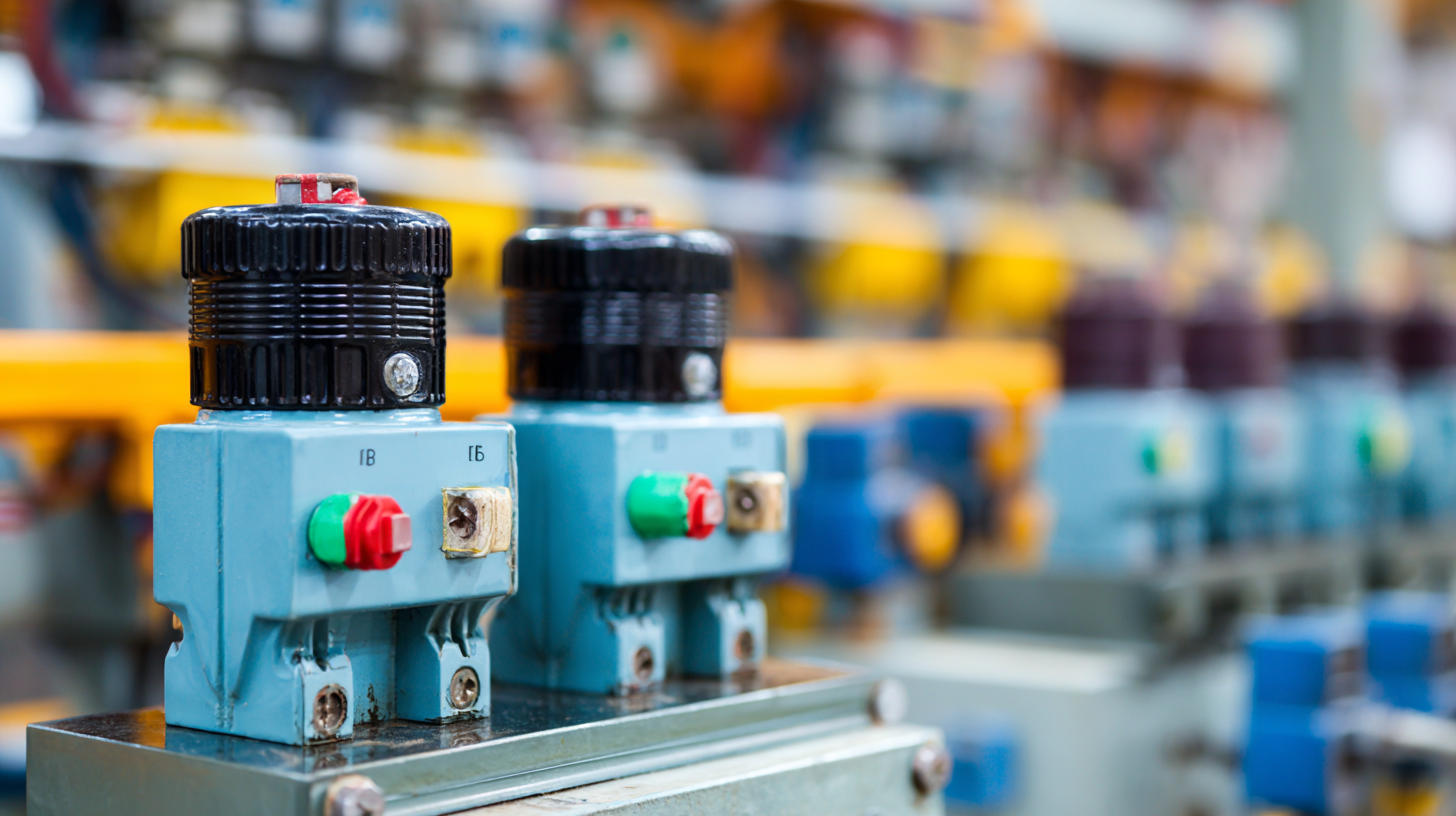

Two hand safety relays are a critical component in workplace safety, especially in environments with machinery that poses potential hazards to operators. These devices require the simultaneous use of both hands to activate a machine, thereby ensuring that the operator's body remains at a safe distance from dangerous moving parts. According to the National Institute for Occupational Safety and Health (NIOSH), implementing such safety measures can reduce the likelihood of hand injuries by over 50% in high-risk industries, such as manufacturing and construction.

The functioning of two hand safety relays is rooted in a simple mechanical principle. When activated, they create a system that needs continuous input from both hands for operation. This not only prevents unintentional activation but also makes it physically impossible for the operator to reach into the danger zone while the machine is running. Furthermore, studies have shown that workplaces employing two hand controls reported a significant decrease in both near-misses and actual accidents, emphasizing their effectiveness in hazard prevention.

**Tips for Implementing Two Hand Safety Relays:**

- Conduct regular training sessions for all employees on the correct usage of two-hand safety relays to reinforce safe operating procedures.

- Regularly inspect and maintain safety relays to ensure they function properly and meet industry standards.

- Encourage a culture of safety by involving employees in discussions about potential hazards and seeking their input on improving safety measures.

Two-hand safety relays are critical components in safeguarding workplaces, particularly in environments involving machinery that pose significant risks. These devices require simultaneous activation from two distinct controls, ensuring that operators cannot accidentally engage equipment with a single hand. This design feature effectively reduces the likelihood of accidents, as it mandates the operator's full attention and minimizes distractions during operation.

Additionally, the essential features of two-hand safety relays include adjustable timing mechanisms, which allow for the customization of response periods based on specific operational requirements. This adaptability is crucial in varying work scenarios, where different levels of control response may be necessary. Furthermore, many modern relays are equipped with diagnostics that provide real-time feedback and error-checking capabilities, enhancing their reliability. These features collectively contribute to a safer working environment by mitigating hazards and promoting responsible operational practices.

Implementing two hand safety relays in a workplace is a critical step towards enhancing safety and preventing workplace hazards. These devices require simultaneous activation by both hands before a machine operates, minimizing the risk of accidental or unintended movement that could lead to injuries. According to the National Safety Council, approximately 4,800 workplace fatalities occur each year in the United States, with many cases involving machinery accidents. By integrating two hand safety relays, companies can significantly reduce the potential for such incidents by ensuring that operators are correctly positioned and aware before initiating any action.

To effectively implement two hand safety relays, start by assessing the specific processes and machines in your workplace that pose the highest risk. Conducting a thorough risk assessment will help identify critical control points where these relays can be most beneficial. Next, select appropriate safety relay devices that comply with industry standards, such as ISO 13851, which outlines the use and requirements for two hand control systems. After installation, ensure that all employees receive comprehensive training on the new safety measures. According to a report from the European Agency for Safety and Health at Work, organizations that prioritize safety training experience a 25% reduction in workplace incidents. By following these steps, your organization can foster a safer working environment and significantly mitigate the risks associated with machinery operation.

Two-hand safety relays are critical components in safeguarding workplaces, particularly in operations involving hazardous machinery. Compliance with established safety standards, such as ISO 13851, is paramount in ensuring these relays effectively mitigate risks. According to a report by the International Association for Safety and Health at Work (IASHA), machinery accidents constitute a significant portion of workplace injuries, with approximately 25% attributable to improper use of safety devices. This underscores the necessity for compliance with safety regulations surrounding two-hand controls, which are designed to prevent accidental activation of hazardous machinery by requiring simultaneous operation.

The importance of adhering to compliance standards for two-hand safety relays is further highlighted by the Occupational Safety and Health Administration (OSHA), which mandates effective safeguarding measures to protect workers. Research indicates that workplaces implementing compliant safety systems, including two-hand safety relays, can reduce accident rates by up to 60%. By understanding and prioritizing these compliance standards, employers not only enhance the safety of their operations but also foster a culture of responsibility and care for employee well-being.

Training employees on the proper use of two-hand safety relays is essential for maintaining a safe workplace. First and foremost, employees should receive comprehensive training that covers the fundamental principles of two-hand safety relays. This includes understanding how these devices work, the reasons for their use, and the potential hazards they help mitigate. Hands-on training sessions can be particularly effective, allowing employees to interact with the equipment directly and see its function in real-time scenarios.

In addition to initial training, ongoing education plays a crucial role in reinforcing safe practices. Regular refresher courses can help ensure that employees remain vigilant and aware of the importance of using two-hand safety relays correctly. Incorporating practical drills and assessments can further solidify their understanding and readiness to respond appropriately in various situations. By fostering a culture of safety and encouraging open communication about safety concerns, organizations can significantly reduce the risk of workplace accidents related to machinery operation.