In the realm of industrial automation, safety remains a paramount concern, particularly in environments involving heavy machinery and automated processes. The Two Hand Safety Relay plays a crucial role in enhancing operational safety by ensuring that machines can only be activated when both hands of the operator are engaged with control devices, thus minimizing the risk of accidental starts and injuries. According to a report by the Occupational Safety and Health Administration (OSHA), over 70% of industrial accidents stem from inappropriate machine operation, highlighting the urgent need for effective safety mechanisms. By implementing Two Hand Safety Relays, industries can significantly decrease the incidence of workplace accidents, fostering a safer environment while also complying with stringent safety regulations. This article will delve into the functionality, advantages, and best practices for integrating Two Hand Safety Relays into industrial automation systems, emphasizing their essential role in protecting workers and optimizing operational efficiency.

In the realm of industrial automation, operator safety is paramount, and two hand safety relays play a crucial role in achieving this goal. These devices require the simultaneous actuation of both hands by the operator to initiate a machine operation, significantly reducing the risk of workplace injuries. According to the National Institute for Occupational Safety and Health (NIOSH), implementing such safety measures can decrease the likelihood of hand injuries by as much as 40%. This statistic underscores the effectiveness of two hand safety relays in protecting workers from hazards associated with automated machinery.

Furthermore, industry standards such as OSHA and ISO 13851 advocate for the use of two hand controls as part of a comprehensive safety strategy. These relays not only prevent unintentional machine movements but also foster a culture of safety within manufacturing environments. A recent report by the International Safety Equipment Association (ISEA) indicates that companies employing two hand safety systems experience a 30% reduction in accident rates compared to those that do not. This data reinforces the necessity of integrating two hand safety relays into industrial systems, ensuring that operators can perform their tasks with enhanced safety and confidence.

The Two Hand Safety Relay is an essential component in ensuring safety in industrial automation settings. This device requires the operator to use both hands to initiate a machine operation, significantly reducing the risk of accidents. As the industrial safety market is set to surge to USD 12.39 billion, the demand for such advanced safety solutions is increasingly recognized. The necessity for strict adherence to safety regulations and the implementation of state-of-the-art safety technologies underscore the importance of Two Hand Safety Relays in modern machinery.

Key features of Two Hand Safety Relays include their ability to prevent unintentional machine start-ups and ensure that operators cannot engage machinery while in the danger zone. The global machine safety market is estimated to reach $7.0 billion by 2029, indicating a robust growth trajectory that emphasizes the increasing integration of safety devices like Two Hand Safety Relays into various industrial applications. As industries continue to prioritize safety, investing in these relays not only complies with regulatory requirements but also promotes a culture of safety within the workforce.

| Feature | Description | Benefits | Application Areas |

|---|---|---|---|

| Dual Control | Requires simultaneous activation of two buttons | Enhances operator safety by ensuring awareness | Robotic automation, press machines |

| Emergency Stop | Integrated emergency stop functionality | Quick response to dangerous situations | Assembly lines, CNC machines |

| Robust Design | Durable components for harsh environments | Increased reliability and reduced downtime | Heavy machinery, outdoor equipment |

| LED Indicators | Visual signals for operational status | Improved monitoring and troubleshooting | Control panels, safety stations |

| Modular Configuration | Flexible design for various applications | Customization to meet specific safety needs | Manufacturing, packaging systems |

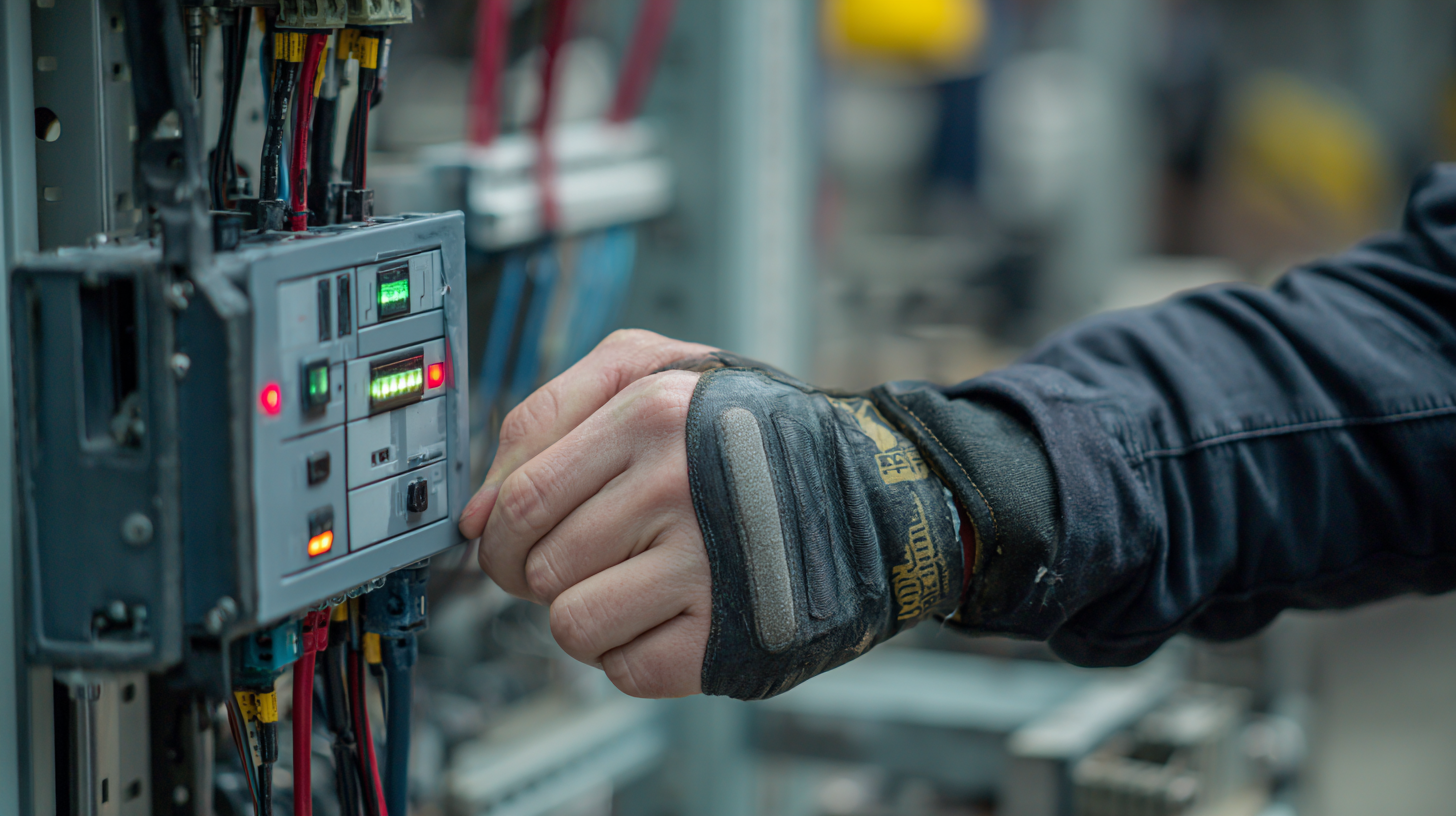

When installing a two-hand safety relay, it's crucial to follow a systematic approach to ensure both safety and functionality. Begin by choosing a suitable location for the relay, ensuring it’s within easy reach and complies with applicable safety standards. Next, gather all necessary tools and components, including the relay unit, wiring, and safety switches.

As you connect the wiring, adhere to the manufacturer's wiring diagrams to avoid incorrect configurations. Pay special attention to the integration of the safety switches, which should allow operation only when both hands are engaged. To enhance reliability, it's beneficial to test the system after installation using safety validation tools, ensuring that all safety modes function correctly.

**Tip:** Always ensure the power is off before starting the installation to prevent electrical hazards. Additionally, consider labeling wires and connections for future reference during maintenance or troubleshooting.

After the setup is complete, conduct regular maintenance checks and functional tests to verify that the safety relay continues to perform optimally. By doing so, you’ll help maintain a safe working environment in your facility.

Maintaining two-hand safety relays in industrial automation is crucial for ensuring worker safety and compliance with safety regulations. Regular inspection and testing of the safety relay system should be part of the maintenance routine. Operators should check the functionality of both push buttons to ensure they are operational and positioned correctly. Additionally, ensuring that the relays are free from dust and debris can prevent malfunctions, which may lead to unsafe working conditions.

Another best practice is to keep a log of maintenance activities and any issues encountered. This documentation can help track the reliability of the safety relays over time and identify patterns that may require further investigation. It is also important to train employees on the correct use of safety relays and the significance of adhering to safety protocols. This training should include instructions on what to do in case of a failure, such as how to safely stop machinery and alert maintenance personnel. By fostering a culture of safety and consistent maintenance practices, industries can enhance the effectiveness of their two-hand safety relay systems.

In the realm of industrial automation, compliance with safety standards for safety relays is paramount. Safety relays serve a critical role in machinery and equipment, ensuring operational safety and minimizing risks. According to the International Electrotechnical Commission (IEC), compliance with standards such as IEC 61508 is essential for ensuring functional safety in industrial applications. This standard provides a framework for establishing the safety integrity level (SIL) required for safety functions, making it a crucial guideline for industries that utilize safety relays.

Furthermore, the recent Market Research Future report highlights that the global safety relay market is expected to grow by approximately 8.5% annually over the next five years, driven by heightened regulatory demands and increasing awareness of safety protocols in the workplace. As industries embrace automation, adhering to compliance standards becomes even more critical. Not only does it protect workers from potential hazards, but it also enhances overall operational efficiency. Ensuring that safety relays meet regulatory requirements is not merely a legal obligation but a strategic move to foster a safer and more reliable industrial environment.

This chart illustrates the compliance standards for safety relays across different industries, showcasing the percentage of industries implementing two-hand safety relays to enhance operational safety.