In the realm of industrial automation, choosing the right Safety Light Curtain is crucial for ensuring worker safety. Renowned expert John Matthews states, "A well-chosen Safety Light Curtain can prevent accidents and save lives." His insights reflect the significant role these devices play in modern workplaces.

Selecting the right Safety Light Curtain is not just about features. It involves understanding specific automation needs. The process requires careful consideration of application environments and potential hazards. Factors such as beam pattern and response time significantly impact effectiveness. The wrong choice can lead to unsafe conditions and risks that could have been avoided.

Every factory or workshop has unique challenges. Companies often overlook the need for customized solutions. Investing time in understanding these requirements is vital. The perfect Safety Light Curtain should blend seamlessly with existing automation systems while providing the necessary protection. Reflecting on past decisions can guide organizations toward better safety measures. The right choice truly matters in protecting lives.

Safety light curtains are essential for ensuring worker safety in automated environments. These devices create an invisible barrier using light beams. When an object or person interrupts the light, they trigger a safety response. This prevents accidents, reducing the risk of injury. Understanding how these curtains operate is crucial for designing safe workspaces.

Choosing the right safety light curtain can feel overwhelming. Different settings require different specifications. For instance, the height and width of the light curtain must fit the specific application. Settings with faster machinery may need more sensitive models. This specificity can lead to challenges; workers might not always recognize the risks involved. Some may try to bypass the system, leading to potential hazards.

Moreover, compatibility is an important consideration. Not all safety light curtains integrate well with existing machines. This mismatch can create gaps in safety protocols. Regular assessments are necessary to identify these issues. Manufacturers must continually evaluate their safety features to keep up with technological advancements. The importance of this vigilance cannot be overstated; a lapse in safety can have dire consequences.

When choosing a safety light curtain, several key factors must be considered. The most important is the application area. Different environments pose unique challenges. For example, a manufacturing floor might have obstacles that need avoiding. Assessing the surroundings helps in selecting the right model.

Another essential factor is the height and width of the light curtain. It should cover the necessary area of operation completely. Inadequate coverage can lead to hazards. Additionally, think about resolution. Higher resolution ensures better detection. However, it could also increase costs.

Furthermore, the response time is critical. A quick response can prevent accidents effectively. Be mindful of the integration with existing systems. Some setups may require specific compatibilities. Evaluating these elements ensures that the safety light curtain meets your automation needs.

Safety light curtains are vital for ensuring worker safety in automated environments. They serve as barriers to prevent accidents involving machinery. Different types cater to various applications, and understanding them is crucial for effective safety implementation.

There are two main types of safety light curtains: Type 4 and Type 2. Type 4 offers higher safety levels, suitable for high-risk areas. They provide additional features like self-checking facilities. Type 2 light curtains are more basic. They are often used in less hazardous environments where the risk is lower.

Tip: Assess the specific risks in your workplace when selecting a type. Consider factors such as machine speed and the nature of tasks performed.

The installation location also matters. Mounting height and angle can affect performance. Incorrect installation leads to gaps in protection. Always account for potential safety breaches.

Tip: Regularly review your safety protocols. Mistakes in risk assessment can jeopardize safety. Keeping a checklist can help maintain compliance and ensure protection.

When selecting a safety light curtain for automation, evaluating technical specifications and compliance standards is crucial. Light curtains act as a protective barrier. They prevent accidental injuries during machine operations. Key specifications include detection range, resolution, and response time. A shorter response time can enhance safety.

Compliance with industry standards is essential. It guarantees the light curtain meets safety regulations. Different regions may have specific compliance requirements. Check if the product aligns with local and international standards. This ensures durability and reliability in a working environment.

It’s also important to consider the installation process. Complicated setups may lead to misalignment. Regular maintenance checks are necessary to keep the system functioning correctly. Sometimes, users overlook the need for periodic testing. This can compromise safety. Evaluating the safety light curtain thoroughly involves attention to detail. Always remain aware of evolving standards. It aids in making informed decisions.

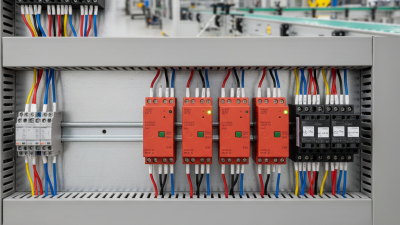

When implementing safety light curtains, careful integration is crucial. Research indicates that proper system integration can reduce workplace accidents by up to 50%. This data highlights the importance of ensuring compatibility with existing machinery.

Employers should assess their current automation needs. Evaluate the area of operation and possible hazards. Consulting with a safety expert can provide insights into the ideal specifications for your system. Ensure that the light curtains are positioned correctly. Misalignment can lead to gaps in safety coverage.

Consider factors like signal processing and response times. A lag in response can create dangerous situations. Studies show that a response time of less than 20 milliseconds is ideal for effective protection. Adequate training for staff on safety protocols is also needed. Human error remains a significant risk factor. It's clear that achieving optimal safety requires a flexible approach and ongoing reflection.