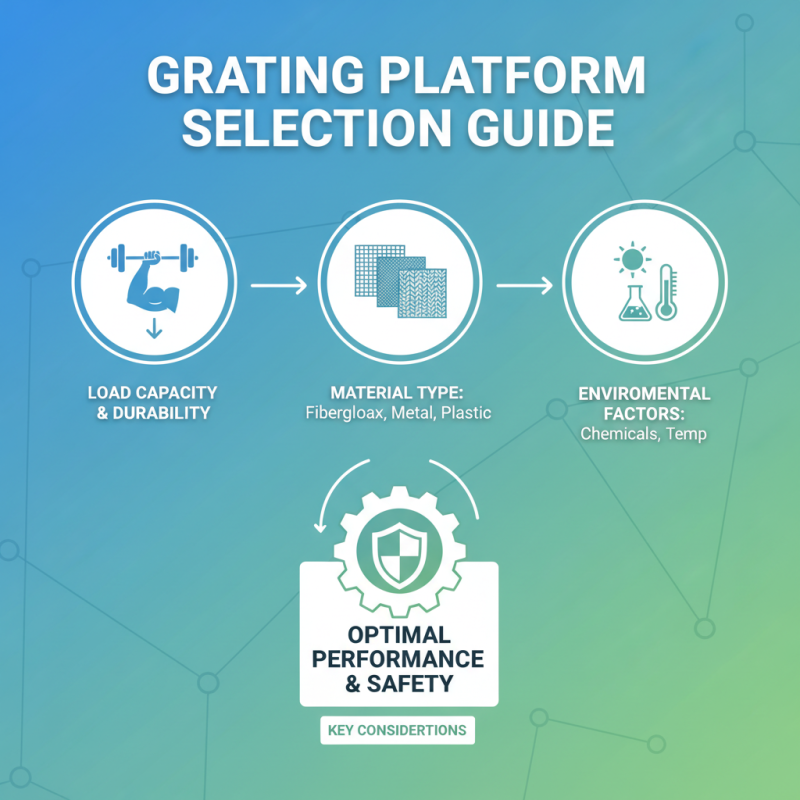

When it comes to selecting the right grating platform for your specific applications in 2023, the process can seem daunting. With a plethora of options available, understanding the unique requirements of your project is crucial to making an informed decision. A grating platform serves as a vital component in various industries, providing safety, durability, and functionality for both industrial and commercial settings. Whether you need it for flooring, walkways, or drainage systems, this choice directly impacts the overall performance and aesthetic of your space.

To facilitate your selection, it’s essential to consider several factors such as material type, load-bearing capacity, anti-slip features, and maintenance requirements. Each attribute plays a significant role in ensuring the grating platform you choose meets the demands of your environment while also enhancing safety. Additionally, understanding your specific needs—whether it's for heavy-duty industrial use or light pedestrian traffic—will guide you in narrowing down the possibilities. By addressing these key considerations, you can confidently choose a grating platform that not only satisfies standards but also stands the test of time.

When it comes to selecting the best grating platform for your needs in 2023, it's crucial to understand the various types available in the market today. Grating platforms are commonly used in industrial, commercial, and environmental applications, designed to provide safe and efficient surfaces for foot traffic and equipment. According to the latest industry reports, the global grating market is projected to grow at a CAGR of around 5% over the next few years, highlighting the importance of choosing the right type to meet your specific requirements.

The most common types of grating platforms include fiberglass reinforced plastic (FRP), metal, and plastic. FRP grating is renowned for its durability and resistance to corrosive environments, making it ideal for chemical processing and wastewater treatment facilities. On the other hand, metal grating, particularly made of steel or aluminum, offers exceptional strength and load-bearing capabilities, which is perfect for industrial settings where heavy machinery is in use. Plastic grating, while generally lighter and more cost-effective, is suitable for areas that require less structural support, such as walkways in parks or residential areas. Understanding these distinctions can significantly affect safety, maintenance, and overall cost-effectiveness.

| Type of Grating | Material | Application | Load Capacity | Price Range |

|---|---|---|---|---|

| Steel Grating | Carbon Steel / Stainless Steel | Industrial Flooring | 500 - 1500 lbs | $15 - $50 per square foot |

| Fiberglass Grating | Fiberglass Reinforced Plastic | Chemical Processing | 200 - 1000 lbs | $30 - $70 per square foot |

| Aluminum Grating | Aluminum | Walkways and Platforms | 500 - 1200 lbs | $25 - $65 per square foot |

| Plastic Grating | Polymer | Pool Decks and Patios | 100 - 600 lbs | $20 - $50 per square foot |

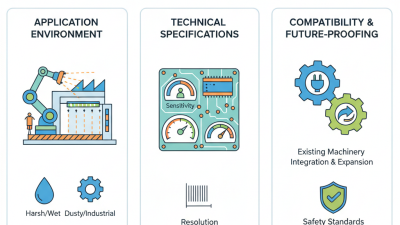

When selecting the best grating platform for your needs, several key factors must be considered to ensure optimal performance and safety. First, evaluate the load capacity required for your specific application. Different materials such as fiberglass, metal, or plastic offer varying levels of strength and durability. Consider the weight and frequency of use, as well as any potential impacts the grating may experience. Additionally, think about environmental factors such as exposure to chemicals or extreme temperatures, which can influence material choice.

Another critical aspect is the design of the grating itself. Slip resistance is paramount, especially in areas prone to moisture or spills. Look for textured surfaces or designs that provide improved traction. Furthermore, the spacing of the grates is essential; it should be tight enough to prevent objects from falling through while allowing for adequate drainage. Aesthetics might also play a role, depending on whether the grating will be exposed to public view. Balancing functionality with visual appeal can enhance the overall effectiveness of the grating in your space.

When evaluating load capacity and durability for industrial grating applications in 2023, it’s essential to consider the specific requirements your application demands. Load capacity is often the first consideration; grating materials are engineered to support varying weights based on their design and construction. For instance, a survey conducted by the Industrial Grating Institute indicates that steel grating can support up to 1,000 pounds per square foot depending on bar configuration and spacing. This makes steel grating particularly suitable for heavy-duty applications in sectors like manufacturing and heavy construction.

Durability is another critical aspect, especially for environments exposed to harsh conditions. According to a report by the Composites Industry Association, fiberglass-reinforced plastic (FRP) grating offers superior resistance to corrosion and UV damage compared to traditional materials, making it ideal for chemical processing facilities. Moreover, FRP grating can last up to 30 years under normal conditions, significantly reducing maintenance costs and downtime associated with replacement. In environments where chemical exposure is a concern, the load capacities of FRP typically range from 300 to 600 pounds per square foot, making it a robust choice for many industrial applications. These factors underline the importance of selecting the right material based on load requirements and environmental durability to achieve optimal performance.

When selecting a grating platform in 2023, a key consideration is the cost-effectiveness of various grating solutions. According to a report by the Global Gratings Industry Association, the average price range of industrial grating systems varies significantly, with costs typically spanning from $5 to $25 per square foot, depending on the material and load capacity. For instance, while steel grates offer durability and strength, their higher initial expense may not be justifiable for all applications. In contrast, fiberglass and plastic grating solutions tend to be lighter and more resistant to corrosion, often making them a more cost-effective choice in environments exposed to harsh chemicals.

Moreover, a comparative analysis highlights that the total lifecycle cost of grating can provide deeper insights beyond initial purchase prices. The National Association of Grating Products suggests factoring in maintenance, replacement frequency, and operational efficiency into the overall cost assessment. For example, although a cheaper grating option might save money upfront, it could incur higher long-term maintenance costs or reduced safety performance, leading to potential losses. Therefore, evaluating cost-effectiveness should encompass not just the purchase price, but also the longevity and reliability of the grating solution under specific working conditions, ensuring the chosen platform meets both performance and budget requirements effectively.

When selecting the best grating platform for your needs in 2023, understanding industry standards and certifications is crucial. Numerous organizations and regulatory bodies set forth guidelines that ensure safety, quality, and performance of grating products. Key certifications to look for include those from the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), which provide benchmarks for load-bearing capacity and slip resistance. Additionally, consider platforms that meet the requirements of the National Fire Protection Association (NFPA) for environments where fire safety is a concern.

Tips for choosing the right grating platform include assessing the specific environmental conditions it will face, such as exposure to chemicals, moisture, or extreme temperatures. Ensure that the selected platform complies with relevant certifications to guarantee its durability and safety. It's also beneficial to consult with professionals in the field who can recommend products that meet both your operational needs and the necessary industry standards.

Always prioritize grating options with documented tests and evaluations, as these can provide peace of mind regarding their structural integrity. Remember, the best platform isn't just about the materials used; it's also about how well it adheres to safety standards and performs in your particular application.