When it comes to ensuring workplace safety, choosing the right Safety Light Curtain Controller is crucial. These controllers play a vital role in integrating safety measures into various automated processes by detecting the presence of individuals in potentially hazardous areas. As technologies evolve, a wide array of options is available, making the selection process both exciting and overwhelming. Understanding your specific needs, such as the application environment, required sensitivity, and compliance with safety standards, can significantly impact the effectiveness of your safety system.

In this guide, we will explore key factors that should influence your decision-making process when selecting a Safety Light Curtain Controller. We will discuss the importance of compatibility with existing machinery, the technical specifications necessary for optimal performance, and the significance of scalability for future expansions. By focusing on these elements, you can make a more informed choice that not only enhances the safety of your operations but also promotes efficiency and productivity in the workplace.

Safety light curtain controllers are essential components in industrial safety systems, designed to safeguard personnel operating near machinery. Understanding the fundamentals of these controllers is crucial for selecting the right one for specific applications.

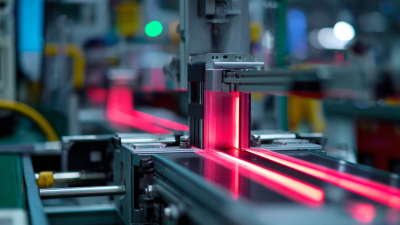

At their core, safety light curtain controllers work by interpreting the signals from light curtains, which are devices that create an invisible barrier of light beams. When an object or person interrupts these beams, the controller typically triggers a safety response, such as stopping the machinery or activating an alarm.

When evaluating safety light curtain controllers, it's important to consider features such as response time, sensitivity, and the types of interfaces used for integration with existing safety systems. Additionally, one should assess the operating environment, including factors like ambient light conditions and potential physical obstructions, which may affect the performance of the light curtains.

Controllers can also vary by the number of channels they support, impacting how many light beams can be monitored at once. By grasping these basic principles, users can make informed decisions tailored to their safety requirements, ensuring optimal protection and compliance in their operations.

When selecting a safety light curtain controller, key features play a vital role in ensuring optimal performance and safety compliance. One of the primary considerations is the response time of the controller. A fast response time is essential to quickly detect any interruptions in the safety curtain, minimizing the risk of accidents. Look for controllers that offer adjustable response times to cater to different operational environments, ensuring maximum efficiency and safety.

Another important aspect to consider is the compatibility with various safety light curtain systems. The controller should seamlessly integrate with existing setups, allowing for easy installation and configuration. Additionally, ensure that it supports multiple safety categories (such as Type 2 or Type 4) for varying applications. User-friendly interfaces and programmable features are also beneficial, enabling operators to customize settings according to specific requirements while facilitating easy monitoring of safety functions. Robust connectivity options, including both digital and analog interfaces, will further enhance the controller's versatility and applicability across different machinery and operational scenarios.

| Feature | Description | Importance |

|---|---|---|

| Response Time | The time taken for the controller to respond to an interruption. | High - Ensures quick action in safety scenarios. |

| Number of Channels | The number of separate light beams the controller can handle. | Medium - More channels allow for greater control over large areas. |

| Safety Standards Compliance | Adherence to relevant safety regulations and certifications. | High - Essential for legal operation and user safety. |

| Environmental Rating | Resistance to dust, moisture, and extreme temperatures. | Medium - Important for installations in harsh conditions. |

| Ease of Installation | Simplified processes for mounting the controller. | High - Reduces setup time and complexity. |

| Diagnostic Features | Tools for troubleshooting and ensuring functionality. | Medium - Helps maintain operational reliability. |

| Application Compatibility | Compatibility with various machinery and applications. | High - Vital for ensuring proper functionality. |

When selecting a safety light curtain controller, compatibility with existing safety systems is crucial to ensure seamless integration and functionality. According to a report by the International Electrotechnical Commission (IEC), approximately 30% of accidents in industrial settings can be attributed to inadequate safety measures. Therefore, evaluating how the new controller will interact with current safety measures can significantly impact overall workplace safety.

To assess compatibility, it's important to consider both hardware and software specifications. For instance, the controller should support the same protocols as existing safety systems, such as Safety Integrated Functions (SIL), which denotes the reliability of the safety functions. A study from the National Institute for Occupational Safety and Health (NIOSH) indicates that integrating safety controllers that are not aligned with existing systems can lead to up to a 25% increase in operational downtime during the transition period. This not only incurs additional costs but can compromise worker safety if not addressed properly.

Moreover, regulatory compliance must also be taken into account. The Occupational Safety and Health Administration (OSHA) mandates adherence to specific safety standards, and choosing a compatible controller that meets these requirements ensures that your facility remains compliant while minimizing risks. Therefore, thorough compatibility assessments should be conducted prior to implementing a new safety light curtain controller to safeguard both personnel and equipment effectively.

This bar chart illustrates the compatibility ratings of various safety light curtain controllers with existing safety systems. The ratings range from 0 to 10, indicating how well each controller integrates with the specified systems.

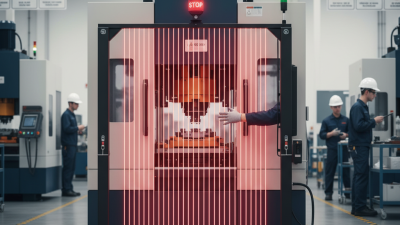

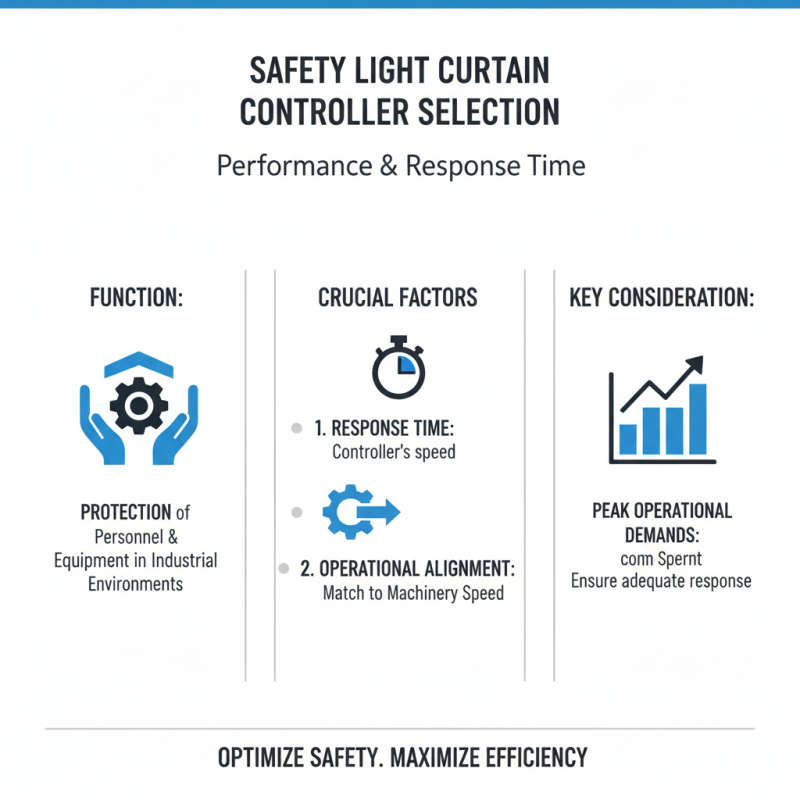

When selecting a safety light curtain controller, evaluating performance and response time requirements is crucial. Safety light curtains are designed to ensure the protection of personnel and equipment in industrial environments. To achieve this, the controller’s performance must align with the operational speed of the machinery it oversees. Understanding the peak operational demands can help in selecting a controller that can adequately respond to these requirements without compromise.

Response time is an equally important factor to consider. This refers to the amount of time it takes for the controller to recognize an interruption in the light curtain and to initiate a safety response. In high-speed applications, a shorter response time is essential to ensure immediate reactions, preventing accidents and minimizing risk. Generally, choosing a controller with a response time compatible with your machinery will enhance safety measures and streamline production processes. When evaluating potential controllers, it’s beneficial to consider both the specific demands of the application and the highest safety standards to maintain a secure working environment.

When budgeting for your safety light curtain controller needs, it’s crucial to start by assessing the specific requirements of your operational environment. Consider the level of protection necessary for your machinery and the potential risks involved. This evaluation will help you determine the appropriate level of technology required, thus influencing your budget. While it might be tempting to opt for the cheapest option, remember that investing in quality and reliability can ultimately save costs by preventing accidents and enhancing productivity.

Next, examine additional features that may impact your budget. Controllers come with various functionalities, including advanced diagnostic tools, connectivity options, and user-friendly interfaces. While these features can increase initial costs, they may lead to significant savings over time through improved efficiency and reduced downtime. Consider long-term operational costs against initial investment to make a well-informed decision. Ultimately, a thoughtful budget allocation that considers both current needs and future growth will ensure that you choose a safety light curtain controller that effectively addresses your safety requirements.