In the realm of effective drainage solutions, the selection of the right **Channel Grating** is paramount for ensuring optimal performance. As industry expert John O’Reilly, a leading engineer in drainage systems, aptly stated, "The right channel grating not only enhances water flow but also minimizes maintenance challenges, ultimately safeguarding infrastructure." This statement underscores the importance of making informed choices in grating types to address specific drainage needs.

With the increasing complexity of urban drainage systems and the pressing demands on infrastructure, understanding the various types of channel grating available is crucial. The decision-making process involves evaluating factors such as material durability, load-bearing capacity, and design compatibility with existing systems. Properly selected channel grating can significantly increase drainage efficiency while reducing the risk of blockage and overflow in stormwater management.

As we navigate through the complexities of choosing the ideal channel grating in 2025, this guide aims to provide essential insights and criteria to streamline the selection process. By leveraging expert opinions, technical specifications, and case studies, readers will be equipped with the necessary knowledge to make choices that not only meet immediate drainage requirements but also contribute to long-term sustainability and efficiency.

Choosing the right channel grating is crucial for optimal drainage efficiency, and several key factors must be considered to enhance performance. First and foremost, the expected flow rate should guide your selection. Assess the volume of water that will be channeled through your system—higher flow rates may require deeper or wider grating options. Additionally, consider the type of debris your drainage system will encounter. If it’s likely to be heavy or bulky, a more robust grating material, such as steel, may be ideal to prevent clogs and ensure longevity.

**Tip:** Always evaluate the environmental conditions in which the channel grating will be installed. For example, regions subject to harsh weather or chemicals might require corrosion-resistant materials to enhance durability and decrease maintenance costs.

Another critical factor is the grating’s load rating, which determines how much weight it can support without risking damage. This is particularly important in areas with high pedestrian or vehicle traffic. The design and spacing of the grating should also align with local regulations to ensure safety and compliance.

**Tip:** Before finalizing your choice, consult with professionals who specialize in drainage solutions. They can provide valuable insights and might help identify specific requirements based on the local infrastructure and drainage needs.

| Dimension | Material | Load Rating | Application | Installation Type |

|---|---|---|---|---|

| 1000mm x 500mm | Cast Iron | Heavy Duty | Roadways | Surface Mounted |

| 750mm x 300mm | Polymer Concrete | Medium Duty | Parking Lots | Inlet Installed |

| 600mm x 400mm | Stainless Steel | High Duty | Industrial Areas | Flush Mounted |

| 500mm x 300mm | Fiberglass | Light Duty | Walkways | Embedded |

| 1200mm x 600mm | Ductile Iron | Extra Heavy Duty | Highway | Bolt Down |

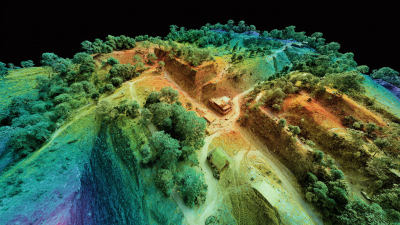

When selecting channel grating for optimal drainage, understanding how grate design influences water flow efficiency and soil erosion is crucial. The shape and material of the grating can significantly affect how water is directed and absorbed, which in turn impacts soil stability. For instance, well-designed grates can help mitigate soil erosion by allowing water to flow efficiently away from the soil surface, reducing the risk of washout and promoting sustainable land management practices.

To enhance water flow efficiency, consider the following tips: First, opt for grates with a larger surface area that allows for greater water intake, minimizing pooling and overflow during heavy rain events. Second, choose grates made from durable materials that can withstand harsh environmental conditions while ensuring long-term performance. Additionally, regular maintenance, such as clearing debris from grates, is vital to preserve optimal functionality and prevent drainage issues.

Incorporating sustainable practices, like biochar application, can further control soil erosion effectively. Biochar not only improves soil structure but also enhances water retention, thereby supporting the health of agricultural lands without compromising drainage efficiency. Such measures, alongside thoughtful channel grating selection, can lead to a more resilient approach to managing water resources and preventing soil degradation.

When selecting the right channel grating for optimal drainage efficiency in urban systems, material choice plays a crucial role, particularly when comparing steel and polymer grates. Steel grates are known for their robustness and durability, making them suitable for high-load areas. However, they are prone to corrosion, especially in environments with heavy metal contamination due to industrial activities. This raises concerns not just about their longevity but also about the impact on water quality, as corroded steel can leach harmful substances into the drainage system.

On the other hand, polymer grates offer excellent resistance to corrosion and are less affected by the harsh chemicals often found in urban wastewater. They are lightweight and easier to install, which can reduce labor costs. With growing concerns over heavy metal pollution and the need for effective wastewater management, polymer grates may represent a more sustainable choice for urban drainage.

Tips: When choosing between steel and polymer grates, consider the specific environmental conditions they will face. For areas prone to heavy metal pollution, polymer grates could be the better option to ensure long-term drainage efficiency. Additionally, always assess the load requirements of the area to avoid potential failures in your drainage system.

When selecting channel grating for drainage systems, one of the most critical factors to consider is load-bearing capacity. According to the American Society for Testing and Materials (ASTM), various grades of grating are tested under specific standards to ensure they meet the required safety and durability criteria. For instance, grates that meet the ASTM A143 standard can withstand loads ranging from 500 to over 2,500 pounds per square foot, making them suitable for heavy traffic areas such as industrial facilities and highways.

In addition to ASTM standards, the National Association of Steel Manufacturers (NASM) emphasizes the significance of understanding local environmental factors that could impact load capacity. For example, grating systems must accommodate not only static loads but also dynamic loads from vehicles and possible accumulations of snow or debris. A comprehensive assessment considering factors such as material type, spacing, and grating design is essential in ensuring optimal drainage efficiency while meeting industry benchmarks for safety. By adhering to these standards, manufacturers can guarantee that their products not only perform effectively under varying conditions but also contribute to long-term infrastructure resilience.

This chart shows the load-bearing capacities of various types of channel gratings, which are essential for optimal drainage efficiency. The data reflects industry standards for safety and durability, helping you make informed decisions when selecting channel gratings.

When selecting the right channel grating for optimal drainage efficiency, maintenance considerations play a critical role in maximizing the lifespan and performance of drainage solutions. Regular maintenance not only ensures continued optimal function but also prevents costly repairs due to neglect. According to a report from the National Association of Drainage Contractors (NADC), regularly cleaned and maintained drainage systems can last up to 50% longer than those that are neglected, emphasizing the importance of a maintenance schedule.

The type of channel grating chosen can also affect maintenance requirements. For instance, grates made from cast iron or heavy-duty composites are often more durable and resistant to wear and tear compared to plastic alternatives. The NADC highlights that systems equipped with modular grating options allow for easier access and cleaning, effectively reducing maintenance downtime. Additionally, integrating filtration systems can help minimize debris buildup, thus enhancing drainage efficiency and extending the lifespan of the entire drainage system. Engaging professional maintenance services at regular intervals can mitigate potential disruptions, ensuring that drainage systems perform efficiently and effectively throughout their operational life.