In the world of precision engineering and manufacturing, the significance of accurate measurements cannot be overstated. One critical component that plays a crucial role in ensuring optimal performance in various applications is the Bottom Dead Center Detector (BDC Detector). According to a recent report from Market Research Future, the market for BDC detectors is projected to grow at a CAGR of 8% from 2023 to 2030, underlining their increasing importance across industries such as automotive, aerospace, and heavy machinery. These detectors ensure that machinery operates efficiently and within safe parameters by accurately identifying the bottom dead center position in cyclic operations.

Dr. Emily Carter, a renowned expert in motion control systems, emphasizes the necessity of selecting the right Bottom Dead Center Detector for specific applications: “The precision with which a BDC detector functions can significantly influence the overall performance and longevity of mechanical systems.” It is imperative to weigh factors such as sensitivity, durability, and installation ease when choosing a BDC detector, as these elements can directly impact the effectiveness of your machinery. This article aims to guide industry professionals in making informed decisions regarding the selection of the best Bottom Dead Center Detector, ensuring that their equipment operates flawlessly and efficiently.

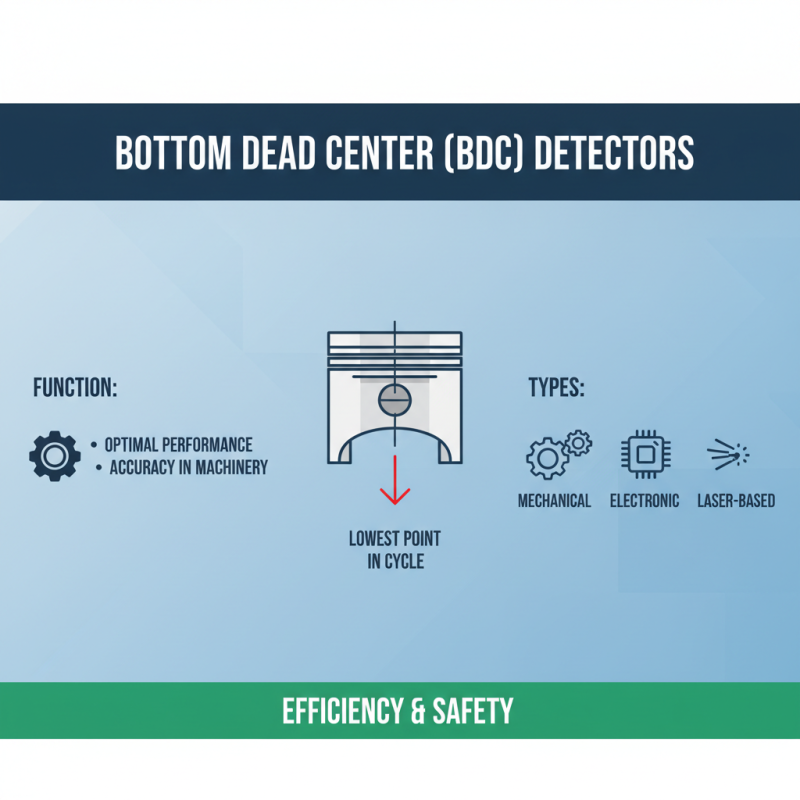

Bottom Dead Center (BDC) detectors are essential tools used in various engineering and manufacturing applications to determine the exact position at which a moving component, such as a piston, reaches its lowest point in a cycle. Essentially, understanding the BDC and its detectors helps ensure optimal performance and accuracy in machinery, which is critical for efficiency and safety in operations. Different types of BDC detectors include mechanical, electronic, and laser-based systems, each offering unique advantages depending on the specific application requirements.

For instance, mechanical BDC detectors, known for their reliability and simplicity, work effectively in applications where precision is less critical. On the other hand, electronic and laser systems provide enhanced accuracy and faster response times, making them ideal for high-speed engines and sophisticated manufacturing processes. According to industry reports from the Machinery and Equipment Manufacturers Association (MEMA), demand for high-precision BDC detectors has grown approximately 15% annually due to increasing automation in production environments.

Tips: When selecting a BDC detector, consider the operating conditions such as temperature, vibrations, and the type of material being measured. Additionally, ensure that the detector's measurement range aligns with your specific application needs. For those in high-performance settings, opting for advanced electronic or laser-based BDC detectors might mitigate the risks of inaccurate readings, thus preventing costly downtimes or mechanical failures. Always consult technical specifications and user reviews to make informed decisions.

When selecting the best Bottom Dead Center (BDC) detector for your applications, it is crucial to consider several key features that can significantly impact performance and accuracy. One of the most important attributes to assess is the measurement range. According to a recent industry report, a detector that can accurately identify BDC across a wide range of motion can enhance the reliability of machining operations, particularly in complex machining scenarios where precision is paramount. Systems with a measurement range of at least ±0.01 mm are preferred in high-precision industries.

Another critical feature to evaluate is the detector’s response time. Fast response times enable real-time monitoring, allowing for immediate adjustments to be made during operations. A study published by the International Journal of Manufacturing Technology highlighted that systems with a response time of less than 10 milliseconds significantly reduce downtime and improve overall efficiency in production lines. Additionally, ease of integration with existing machinery should not be overlooked; devices that offer user-friendly interfaces and compatibility with various control systems can drastically minimize implementation time and costs.

Furthermore, durability and environmental resistance are essential considerations, particularly in demanding manufacturing environments. Many detectors are subjected to harsh conditions, including temperature fluctuations and exposure to moisture and dust. A recent survey indicated that detectors designed with IP67 ratings or higher are favored in industries like automotive and aerospace, as they demonstrate enhanced performance in extreme conditions. By focusing on these critical features, you can choose a BDC detector that not only meets but exceeds the operational requirements for your specific applications.

| Feature | Description | Importance | Recommended Value |

|---|---|---|---|

| Measurement Range | The range over which the detector can accurately measure positions. | High | 0 to 500 mm |

| Accuracy | The precision of the measurements made by the detector. | Very High | ±0.01 mm |

| Response Time | The time taken for the detector to respond to changes in position. | Moderate | < 20 ms |

| Interface Type | The communication interface for connecting to other devices. | High | USB/Serial |

| Durability | Resistance to environmental factors such as dust and moisture. | Very High | IP67 |

| Power Supply | The required power source to operate the detector. | Moderate | 5V DC |

When selecting a bottom dead center (BDC) detector for specific applications, evaluating the accuracy and sensitivity of the detection technology is crucial. Accuracy refers to the ability of the BDC detector to identify the precise position of the bottom dead center, which is vital in mechanical systems where even slight misalignments can lead to performance degradation or mechanical failure. A high-accuracy detector will minimize errors in positioning, ensuring that machinery operates within optimal parameters. This is especially important in industries like automotive and manufacturing, where precision is paramount.

Sensitivity, on the other hand, refers to the detector's capacity to respond to slight changes in motion or position. A sensitive BDC detector can provide real-time feedback on the machine's status, allowing for timely adjustments and optimizing operational efficiency. In applications involving high-speed machinery or delicate components, having a detector with enhanced sensitivity can prevent damage and extend the lifespan of the equipment. Thus, when evaluating BDC detection options, it is essential to consider both accuracy and sensitivity to ensure that the selected technology aligns with the operational demands and enhances the overall performance of the system.

This chart illustrates the accuracy and sensitivity of various Bottom Dead Center detectors based on hypothetical performance metrics.

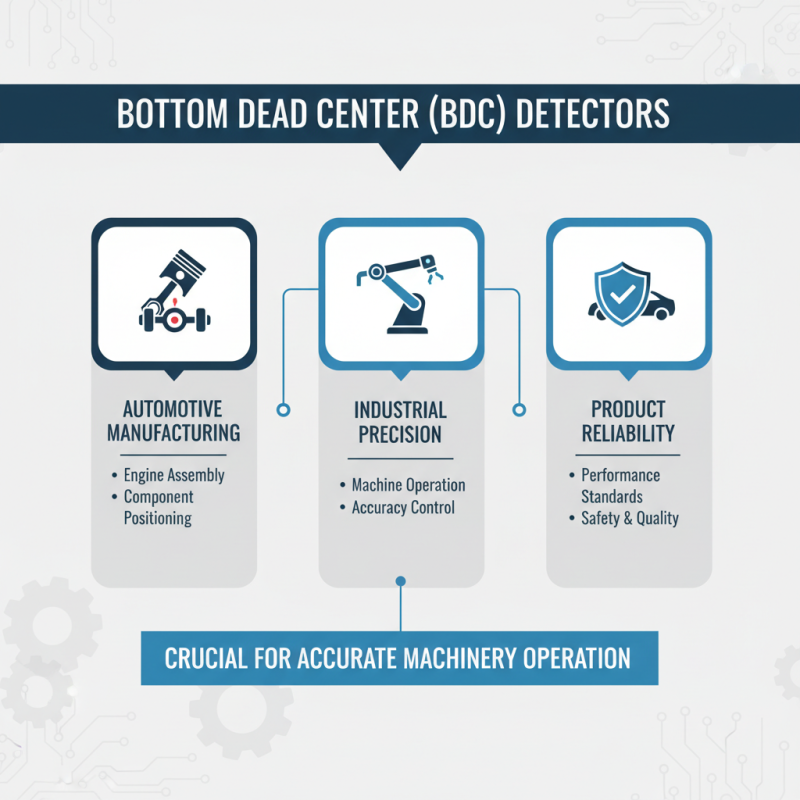

Bottom dead center (BDC) detectors play a crucial role in various industrial applications, particularly in sectors where precision in machinery operation is paramount. For instance, in automotive manufacturing, BDC detectors are utilized to ensure that engines and components are positioned accurately during assembly processes. This accuracy helps in maintaining the performance and safety standards required in automotive production, resulting in better product reliability.

In addition to automotive applications, BDC detectors are also widely used in the robotics and automation industry. These devices facilitate precise movements and calibrations of robotic arms, ensuring that they reach their designated positions without error. This precision is essential in processes such as welding, painting, and assembly, where any deviation can lead to defects and increased operational costs. Moreover, BDC detectors are increasingly finding applications in renewable energy sectors, such as wind turbine manufacturing, where they are utilized to optimize the positioning and functioning of turbine blades for maximum efficiency.

When considering the purchase of a bottom dead center (BDC) detector, a thorough cost analysis is essential to ensure that your investment aligns with your application needs. According to a recent market research report by ResearchAndMarkets.com, the global bottom dead center detector market is expected to grow at a compound annual growth rate (CAGR) of approximately 4.5% over the next five years. This growth is largely driven by advancements in manufacturing technologies and a rising emphasis on automation across various sectors, suggesting that budgeting effectively for these tools is increasingly crucial.

Typically, costs associated with BDC detectors can vary significantly, often ranging from a few hundred to several thousand dollars, influenced by factors such as precision, digital integration, and additional features. A survey conducted by IndustryWeek indicated that 60% of manufacturers consider the total cost of ownership—factoring in maintenance and operational efficiency—when choosing equipment. This comprehensive approach helps businesses avoid common pitfalls associated with underbudgeting, as a lower upfront cost might result in higher long-term operational expenses due to inefficiencies. Therefore, a well-rounded budget that includes initial purchase cost, potential upgrade paths, and ongoing maintenance can lead to optimal performance and investment returns in the long run.